Back

In stock

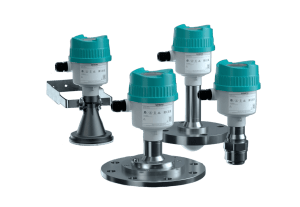

SITRANS LR500 Series Radar Transmitters

SITRANS LR500 series are 80 GHz radar level transmitters for continuous monitoring of liquids, slurries, and solids in storage and process vessels.

-

Description

The series consists of four transmitters:

- SITRANS LR510 – threaded lens antenna for liquids

- SITRANS LR530 – flanged encapsulated antenna for extreme conditions

- SITRANS LR550 – polymeric horn antenna for solids and liquids

- SITRANS LR580 – lens antenna with integrated aiming flange for solids

Benefits

- Programming options to fit your preference – 4-button HMI, Bluetooth® wireless technology with the optional SITRANS AW050 and SITRANS mobile IQ App, or SIMATIC PDM

- Easy installation and commissioning – 80 GHz narrow beam and small size, Quick Start Wizards, and integrated flanges

- Healthy measurement assurance – SITRANS IQ Guard provides monitoring, NE107 diagnostic messaging and quality verification reports

- Advanced signal processing – Process Intelligence with Auto False Echo Suppression and Near Range Suppression

- Process control analytics and optimization – 100,000 point of data logging memory

- Regulatory compliance made easy – 1 mm accuracy in accordance with IEC 60770-1, suitable for APL 2350, low power consumption with an Environmental Product Declaration, and optional Second Line of Defense for toxic material safety

Detail

| SITRANS LR510 | SITRANS LR530 | SITRANS LR550 | SITRANS LR580 | |

|---|---|---|---|---|

| Order No. | 7ML751 | 7ML753 | 7ML755 | 7ML758 |

| Threaded lens antenna for liquid applications |

Flanged encapsulated antenna for extreme conditions |

Polymeric horn antenna for solids and liquid applications |

Lens antenna with integrated aiming flange for solids applications |

|

| Wetted materials | 316L or C22 Alloy, FKM or FFKM seal, Peek lens |

PTFE lens with integral gasket | PP with FKM or EPDM sealing | 316L with FKM or FFKM seal, Peek lens |

| Measuring range | ¾” : 10 m 1″ : 20 m 1½”: 30 m |

1″/DN25: 20 m 2″/DN50: 30 m 3″/DN80 or larger: 120 m |

120 m | 120 m |

| Process connections | Threaded, ¾”, 1″, or 1½” | Flange, 1″/DN25 to 8″/DN200 | Open air or flanges 3″/DN80 to 8″/DN200 |

3″/DN80 to 6″/DN150 |

| Process pressure | Max 40 bar, depending on temperature |

Max 25 bar, depending on temperature |

Max 2 bar | Max 3 bar |

| Process temperature | -40 °C to 250 °C depending on seal type |

-196 °C to 200 °C depending on seal type |

-40 °C to 80 °C | -40 °C to 250 °C depending on seal type |

| Second Line of Defense | Available | Available | N/A | Available |

| Beam Angle | ¾”: 14° 1″: 10° 1½”: 7 / 10° |

1″/DN25: 10° 2″/DN50: 6° 3″/DN80 or larger: 3° |

3° | 3° |

| Air purge connection | N/A | N/A | Optional accessory | Integrated |